During the covid wave, an inefficient and fragmented supply chain scrambled the whole healthcare industry. As a result, the worldwide supply of pharmaceutical products grew to $629 billion in 2019, making it more complex and impenetrable.

Moreover, the global pandemic exposed how the traditional approach of managing a complex web of organization, people, activities, and resources can ruin the supply chain resilience and its effectiveness in recovering from the crisis.

According to a report by Deloitte Health Solutions, the company’s commitment and robust spending is the main reason for achieving supply chain resilience.

In ‘addition, organizations are adapting technology to tackle ongoing disruption (covid pandemic, cyberattacks, international trade tensions). Although technology is critical in achieving supply chain resilience, it is not the only weapon organizations use for this purpose.

What is Resilience in Supply Chain Management?

Resiliency in supply chain management means the company can sense and respond to a supply chain risk. It is the ability of a body to resist disruptive shocks and the capacity to recover from them.

Every industry’s supply chain has issues, and somewhere businesses can’t escape from them. Still, in particular, the healthcare industry we’re talking about has been implanted with gregarious rules and regulations in these few years. Rules like capturing serialization and ensuring traceability are accountable, and the quality must be at par. So to increase the resiliency and consistency in the supply chain, many medical and pharmaceutical companies started adapting automation in a broader sense.

Characteristics Of A Resilient Supply Chain

Works By Optimising Production With Supply Chain Planning

Through correct supply chain planning synced with production optimization, the demand and supply are rightfully optimized, and the production is harmonized. Strategic planning is crucial for achieving resilience in all supply chain components and bringing transparency and flexibility. This forward-looking behavior helps companies to limit the impact of disruptions and shocks and improve overall operations.

Works By Leveraging The Data

Natural threats, geopolitical issues, competitor activity, and sales reports are analyzed digitally through AI and automation to forecast threats and opportunities, leading to supply chain resiliency. The technological adaptation and automation by businesses in the input-output of goods is the enabler of resilience in the supply chain.

Businesses using digital supply chain technology, like machine learning, workforce automation, modern database, and artificial intelligence, can all be used together to spot disruption, trends, and opportunities.

Multiple Supplier And Manufacturer Partners

Due to covid halt, businesses realized the need to have multiple suppliers in contact for a consistent and resilient supply chain. Traditionally, businesses rely on a single supplier and manufacturer to reduce logistics complexity, but if an unexpected halt occurs, it impedes the whole supply of goods. Having multiple supplies gives flexibility and assurance of having a consistent supply of goods.

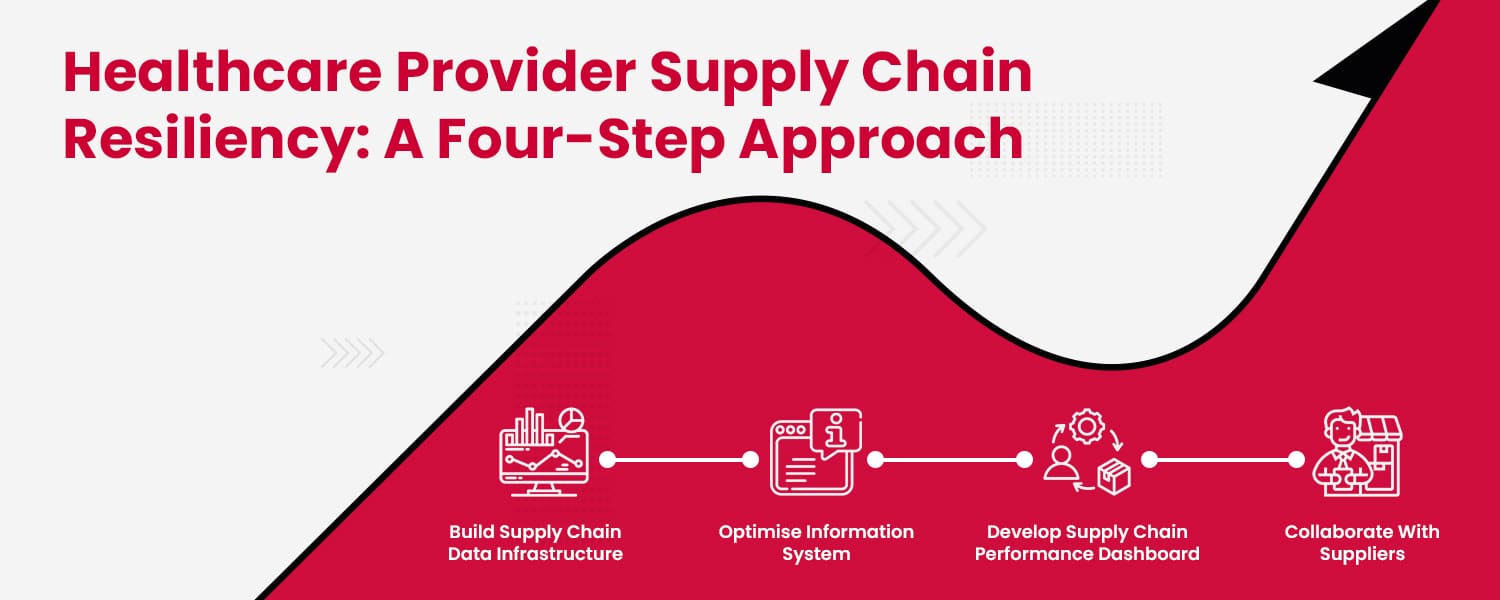

What Are The Four Steps To Developing A Resilient Supply Chain?

To build a resilient supply chain, healthcare leaders should:

1) Build Supply Chain Data Infrastructure

Upgrading the data management system will integrate data between the supply chain and clinical system. You will achieve data accuracy by building data from multiple sources to solve inventory management problems and bring supply chain resilience. Data can be overwhelming, so businesses must use it correctly to improve operations.

2) Optimise Information System

Identify the information system’s strengths and drawbacks and optimize it to remove redundancy in the supply chain. Incorporate an efficient inventory management system, and Enterprise Resource Planning (ERP) management system to implement resilience in the supply chain. Analyze past data, results, and information systems to forecast accurate projections regarding inventory, labor, technology, and logistics requirements.

3) Develop Supply Chain Performance Dashboard

Continuous monitoring of metrics and KPIs is important to achieve supply chain resiliency. Develop a supply chain performance dashboard to monitor supplier performance, inventory management, purchase, and reacquisition.

4) Collaborate With Suppliers

Having a good relationship with multiple suppliers is very important for the timely supply of quality products and raw materials building supply chain resilience.

However, a lack of interest and transparency between you and suppliers and supplier’s suppliers can put your medical business at high risk. Getting a clear view of every stage of the supply chain will bring resilience.

Conclusion

There are disruptions or shocks which are uncontrollable such as natural disasters, regional issues, geopolitical issues, and global pandemics. As an eCommerce business owner or medical company, you can’t control them, but you prepare for them, which builds a resilient supply chain.

A supply chain includes different critical factors and processes, and the slightest inefficiency affects the whole process. One major critical factor is warehousing. eCommerce businesses utilize modern world-class tech-enabled warehouses and fulfillment centers to bring supply chain resilience. If your business is looking for smart warehouses, leverage NimbusPost’s state-of-the-art warehouses and fulfillment centers.