If you want to make your eCommerce business a well-oiled machine, the supply chain would be the oil you only need. However, establishing and running a supply chain is much more complex than you think, and efficient supply chain management is crucial to derailing your competitors. Supply chain management entails the integrated process from resource acquisition and allocation to product development to delivering it to customers. This blog is written as a comprehensive guide to SCM. You’ll learn what it is, how it functions, and its importance in your eCommerce business.

What is Supply Chain Management (SCM)?

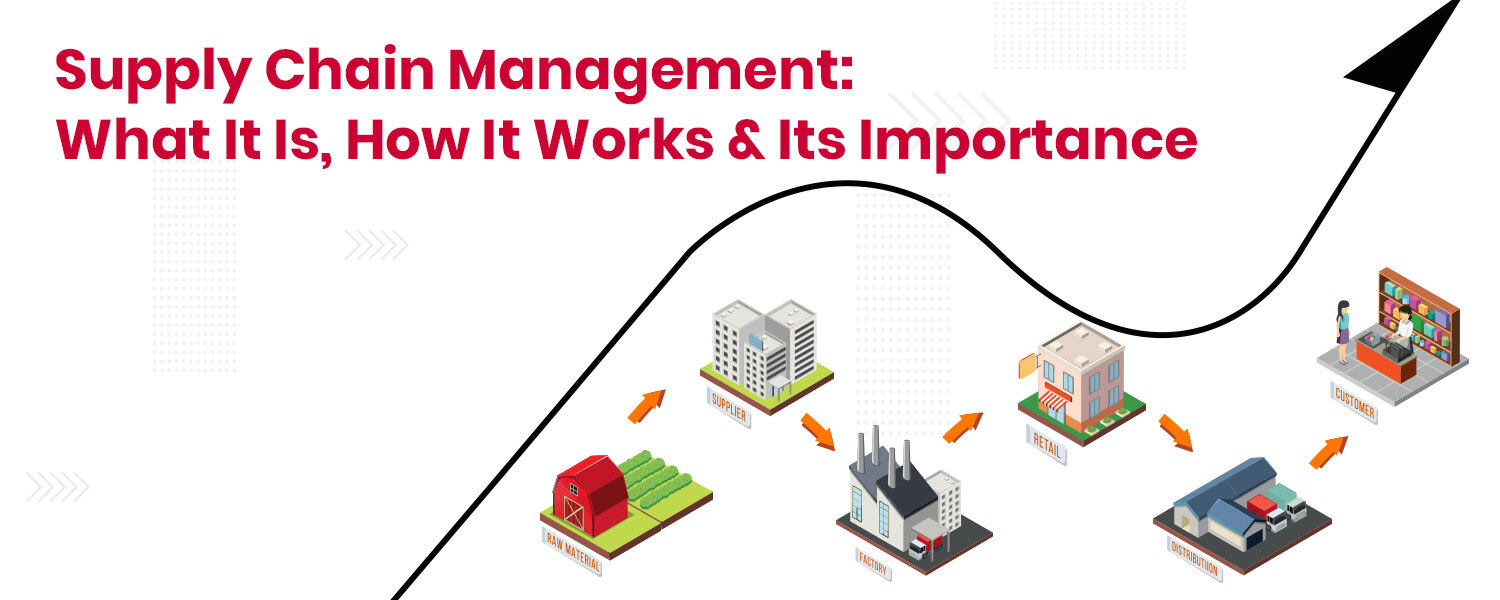

Supply chain management is coordinating and managing all activities involved in sourcing, procurement, conversion, and logistics. It includes the movement and storage of raw materials, work-in-progress inventory, and finished goods from the point of origin to the point of consumption. eCommerce companies that excel at supply chain management can respond quickly to changing market conditions, reduce inventory costs, and improve delivery times, leading to increased customer satisfaction and business growth.

It’s important to understand that supply chain management is not just about logistics and the movement of goods but also about managing relationships, identifying and mitigating risks, and improving overall performance.

Key Takeaways

The key takeaways from supply chain management for eCommerce sellers include:

Optimizing inventory

By understanding customer demand and managing inventory levels accordingly, eCommerce sellers can reduce the risk of stockouts and overstock. This can also help to improve cash flow and reduce holding costs. In addition, you can optimize inventory by using forecasting techniques to predict future demand for products and by implementing inventory management software.

Streamlining logistics

Efficient logistics management can help eCommerce sellers to reduce transportation costs and improve delivery times. This can be achieved by identifying the most cost-effective shipping methods, negotiating favourable terms with carriers, and implementing effective warehouse management practices.

Building strong supplier relationships

Strong relationships with suppliers can help eCommerce sellers secure favorable terms and prices and ensure a consistent supply of goods. This can be achieved by regularly communicating with suppliers, monitoring supplier performance, and identifying potential supply chain risks.

Mitigating risks

Supply chain management involves identifying and mitigating potential risks, such as supplier disruptions, natural disasters, and changes in market conditions. By implementing risk management strategies, eCommerce sellers can minimize the impact of these risks on their businesses.

Utilizing technology

Technology can play a key role in supply chain management by helping eCommerce sellers to improve visibility, automate processes, and make more informed decisions. This can include using software to manage inventory levels, track shipments, and analyze data.

Continuously improving

Continuously monitoring, analyzing, and improving supply chain processes can help eCommerce sellers to reduce costs, improve efficiency, and increase customer satisfaction. This can be achieved by regularly reviewing performance metrics, identifying areas for improvement, and implementing corrective actions.

Additional Read: How to Improve Supply Chain Management?

Explaining Supply Chain Management (SCM)

XYZ Clothing Company is a medium-sized fashion retailer selling clothing and accessories through brick-and-mortar stores and online. The company has experienced steady growth in recent years but has struggled with maintaining consistent inventory levels and meeting customer demand.

XYZ Clothing Company implemented a comprehensive Supply Chain Management (SCM) strategy to address these issues.

The first step in the SCM process was to optimize inventory levels. The company began by using forecasting techniques to predict future demand for products. Then, by analyzing historical sales data, customer demographics and behaviour, and market trends, the company could make more informed decisions about how much inventory to order, when to order it, and how much to keep in stock.

The company also implemented inventory management software to track inventory levels, manage reordering and replenishment, and set up automated alerts for low stock levels. This helped the company ensure they always had enough inventory to meet customer demand without overstocking.

In addition, XYZ Clothing Company implemented just-in-time (JIT) inventory management to reduce holding costs and improve cash flow. By ordering products only as needed, the company could reduce the amount of money tied up in inventory and increase cash flow.

To improve logistics and transportation, the company began to work closely with a select group of reliable carriers to negotiate favourable terms and set up regular delivery schedules. This helped to reduce transportation costs and improve delivery times. The company also set up a new order processing and fulfilment system that allowed customers to track the status of their orders online. This helped to increase customer satisfaction and reduce the number of customer service inquiries.

What Are The Five Basic Steps Of Supply Chain Management?

Planning

Planning is a crucial aspect of supply chain management as it helps eCommerce sellers to anticipate and manage the flow of goods and services. By effectively planning, sellers can ensure that they have the right products in the right quantities at the right time to meet customer demand. Forecasting, budgeting, and setting goals are key elements of Planning. By accurately forecasting demand, eCommerce sellers can avoid overstocking products, leading to increased storage costs and the risk of products becoming obsolete.

Manufacturing

Without manufacturing, eCommerce sellers would have nothing to sell, and customers would have nothing to buy. Therefore, it plays a crucial role in the supply chain by converting raw materials into finished goods ready for distribution and sale.

The manufacturing process you choose will have a significant impact on the efficiency of your supply chain. When choosing a manufacturing process, it is important to consider factors such as lead times, labour costs, and product complexity. There are several different manufacturing processes that eCommerce sellers can choose from, each with their benefits.

- Assembly Line: This is a popular manufacturing process where a product is assembled by a team of workers, each responsible for a specific task. This process is efficient and cost-effective but requires a high level of coordination and communication among the team.

- Mass Production: This process involves producing many identical products using specialised machinery. It is highly efficient and cost-effective but requires a large upfront investment in equipment.

- Flexible Manufacturing: This process allows for producing a wide range of products using a combination of assembly lines and mass production techniques. It is more flexible and adaptable than mass production but is also more expensive.

Sourcing

Sourcing in the Supply chain is the process of identifying and acquiring the goods and services needed to run your business, and it’s a key part of supply chain management. Without proper sourcing, eCommerce sellers would have a hard time keeping their inventory levels up and their costs down.

There are a few key elements to sourcing that eCommerce sellers need to be aware of.

- Identifying and selecting suppliers is the first step. This involves researching potential suppliers, comparing their prices and terms, and ultimately choosing the one that best meets your needs.

- Once you’ve selected a supplier, negotiations come into play. This is where you’ll work out the details of your agreement, such as price, delivery schedule, and payment terms. Managing supplier relationships is also important, as it involves keeping track of supplier performance and addressing any issues that may arise.

Delivering

Logistics and transportation are the engines that keep the supply chain running smoothly and on time. They are responsible for getting products from the manufacturer to the customer. Tracking and monitoring deliveries are important aspects of logistics and transportation and include:

- Keeping track of the location of goods in transit.

- Monitoring delivery schedules.

- Ensuring that goods are delivered on time and in good condition.

By tracking and monitoring deliveries, eCommerce sellers can keep customers informed of the delivery status and address any issues that may arise. There are a variety of delivery modes available to eCommerce sellers. Some popular options include:

- Ground Shipping: This is the most common delivery option and typically the most cost-effective. It’s great for shipping large quantities of goods, but it takes longer to reach the customers.

- Air Shipping: This option is more expensive than ground shipping, but it is much faster. It’s a great option for sellers who need to get goods to customers quickly.

- International Shipping: This option is great for sellers who sell goods to customers in other countries. It’s more expensive than domestic shipping, but it can open up new markets for eCommerce sellers.

Returning

Managing returns is a critical aspect of supply chain management, and let’s face it, it’s just as important as getting the product to the customer in the first place. Returns can happen for various reasons, and eCommerce sellers need to be prepared to handle them promptly and efficiently.

Analyzing return data is an important step, as it helps you to identify common issues, such as defective products or sizing issues. Identifying common issues can help address the problem’s root cause and reduce the number of returns. In addition, implementing a clear and easy-to-understand return policy is also important as it helps reduce the number of returns and makes returning products easier for customers.

SCM vs. Supply Chains

Supply Chain Management (SCM) is a broad and all-encompassing term that refers to managing and optimizing the entire flow of goods and services in a business. It involves coordinating and collaborating with all stakeholders in the supply chain, including suppliers, manufacturers, distributors, and customers.

It also includes strategic and tactical decision-making, such as determining the right manufacturing process, selecting the right suppliers, and managing inventory levels. On the other hand, Supply Chains specifically refer to the physical flow of goods and services. It involves the movement of goods and services from the suppliers to the customers. Supply chains are the backbone of eCommerce businesses, and without them, eCommerce businesses would be unable to function.

Supply Chain Management (SCM) is about managing and optimizing a business’s entire flow of goods and services. For eCommerce businesses, this means forecasting demand, budgeting resources, setting goals, and coordinating with suppliers, manufacturers, and logistics providers to ensure that products are available when customers want them. While supply chains specifically refer to the process of getting the product from the manufacturer to the customer’s doorstep. This means choosing the right delivery option, such as ground shipping, air shipping, local delivery, or international shipping. It also means keeping track of the location of goods in transit, monitoring delivery schedules, and ensuring that goods are delivered on time and in good condition.

What Are The Five Types Of The Supply Chain?

The Continuous Model

The Continuous Model is one of the most traditional models of supply chains. It’s well-suited for businesses that produce a uniform set of goods and can expect a stable level of demand from the market. It is characterised by a steady flow of goods and services, with minimal variation in customer demand. It typically exists in an environment with supply and demand stability, is used by mature supply chains for established brands, and requires minimal variation in the customer demand profile.

PepsiCo is a prime example of a smooth and efficient supply chain model, where they can consistently meet their customers’ demands by maintaining a steady flow of ingredients for their food and beverage products, regardless of the season or market conditions. In addition, they have effectively set up their logistics to ensure a continuous replenishment of ingredients for production and restocking of vendors. This allows them to maintain a large customer base and keep their products readily available.

The Fast Model

The Fast Model is a supply chain model suitable for businesses with product lines with short life cycles. This model is characterized by a quick response to market trends, fast delivery of goods and services, and a flexible and adaptive approach to supply chain management. It’s about being quick on your feet and promptly responding to changing market conditions.

A great example of a company that follows the fast model is Nike. As a leader in active-wear fashion, Nike is constantly setting up delivery systems of new supplies and information to create and then sell new shoes and other apparel before that particular trend’s time has passed. They understand that trends come and go quickly in the fashion industry, so they set up a new fast supply chain for the next wave of trendy products. Nike’s supply chain is focused on speed and flexibility, a key characteristic of the fast model. In addition, they use their strong relationships with suppliers and logistics providers to ensure that they can quickly respond to changes in market conditions.

The Efficient Model

The Efficient Model is a supply chain model crafted for hyper-competitive industries. Under this model, the end goal is to maximize efficiency in every aspect of the supply chain. It is characterized by focusing on proper inventory management, maximizing production equipment and labour output, and reducing costs wherever possible.

The Agile Model

The Agile Model is well-suited for businesses dealing with speciality items where products may require extra care in the supply chain. This model is usually fine-tuned for the effect it is being used for and is known for its expertise in transporting the goods from point A to point B, and not so much for the automation or technology involved. It is characterized by the ability to respond quickly to changes in demand and market conditions and a focus on flexibility and adaptability.

A great example of a company that follows the agile model is ZARA. As a fashion company, ZARA’s success lies in its ability to respond quickly to market conditions and changes in demand. They keep their designers vigilant in spotting new trends. As soon as ZARA’s designers identify a potential trend, they draw sketches and order new materials. ZARA’s supply chain is focused on speed, flexibility, and adaptability, a key characteristic of the agile model. They use their strong relationships with suppliers and logistics providers to ensure that they can quickly respond to market conditions and get new products to customers.

The Custom-Configured Model

The Custom-Configured Model is a supply chain mix of agile and continuous flow methods. It is usually used for prototype design and manufacturing of small batches. This model is characterized by its flexibility and adaptability, as it can be tailored to meet the specific needs of a business. It’s a perfect fit for businesses that operate in rapidly changing markets and need to respond quickly to changes in demand and market conditions.

For example, Tesla is known for their ability to adapt to market conditions and demand changes quickly. Tesla’s supply chain focuses on speed, flexibility, and adaptability, a key characteristic of the custom-configured model. In addition, they use advanced technology and automation to increase efficiency and reduce costs.

What Are The 3 P’s In The Supply Chain?

Planning

The first P in the supply chain is Planning. This identifies and forecasts the resources, materials, and capacity needed to meet customer demand. Planning helps businesses to anticipate and prepare for changes in demand and market conditions. It also enables businesses to optimize their resources and processes for greater efficiency and cost-effectiveness.

Partners

Partners. This refers to the suppliers, vendors, and logistics providers businesses work with to source materials, manufacture goods, and deliver products to customers. Partners play a critical role in the supply chain, providing businesses with the resources and expertise needed to meet customer demand and achieve their goals. The role of partners in the supply chain is to provide eCommerce businesses with the resources and expertise they need to meet customer demand and achieve their goals. This includes sourcing materials, manufacturing goods, and delivering products to customers.

People

This refers to the employees, managers, and other individuals involved in the Planning, sourcing, manufacturing, logistics, and delivery of goods and services. People play a critical role in the supply chain as they make decisions, manage processes, and ensure that customer demand is met promptly and efficiently. The importance of people in the supply chain cannot be overstated. They are the driving force behind the supply chain and are responsible for making decisions, managing processes, and ensuring that customer demand is met promptly and efficiently.

What is a Supply Chain Management Example?

A common example of supply chain management in practice is the fast-fashion industry. A fashion company like Zara designs and produces clothing quickly in response to the latest trends and then delivers it to their stores worldwide. This requires close coordination and communication between Zara’s designers, suppliers, manufacturers, logistics providers, and retailers to ensure that the right clothing is produced in the right quantities and delivered to the right stores at the right time. This process is called fast-fashion supply chain management.

Importance of Supply Chain Management

Cost efficiency

Cost efficiency is a major benefit of Supply Chain Management. Supply Chain Management enables businesses to optimize their supply chain to reduce costs and increase profitability. By streamlining processes, reducing waste, and identifying areas for cost reduction, eCommerce businesses can lower costs and increase their bottom line.

Improved Quality

Supply Chain Management (SCM) is not only about cost reduction and efficiency but also about ensuring that the products and services delivered to customers are of the highest quality. By implementing quality control and quality assurance processes throughout the supply chain, SCM helps businesses to identify and eliminate defects and improve the overall quality of their products and services. Quality is a key differentiator in today’s market. Customers are willing to pay a premium for a product or service that meets or exceeds their expectations. By implementing SCM, you can differentiate yourself from the competition and ensure that you deliver your customers the highest quality products and services.

Additional Read: How Supply Chain Leaders Promote Culture of Quality

Better Customer Service

Let’s be honest; we all love it when a company goes above and beyond to make us happy. Supply Chain Management (SCM) is about getting the right products to the right place at the right time. By streamlining processes and improving communication and collaboration between suppliers, manufacturers, and distributors, businesses can ensure that they always have the products their customers want on hand. This can lead to shorter lead times, fewer stockouts, and, ultimately, happier customers.

Role of Logistics in Supply Chain Management

The role of logistics in supply chain management is mentioned below:

Planning and Coordination

In logistics, Planning and coordination are key. An eCommerce business has to ensure it provides the right products timely. Otherwise, customers will be left disappointed. Logistics planning and coordination with suppliers are critical to ensure goods’ timely and efficient movement.

Transportation and Distribution

Choosing carriers, routing, and scheduling deliveries are all important factors that must be considered. In addition, logistics data and analytics can improve transportation and distribution efficiency by identifying bottlenecks and inefficiencies in the supply chain.

Additional Read: Top Distribution Metrics and Their Importance in eCommerce Logistics

Inventory Management

Inventory management is another important aspect of logistics. eCommerce businesses must ensure they have the right products in stock to meet customer demand. Therefore, logistics management of inventory levels, including forecasting and reordering of goods, is critical to the success of an eCommerce business.

Reverse Logistics

Reverse logistics is managing returns, repairs, and disposal of goods. It’s an important aspect of logistics that eCommerce businesses need to consider. Logistics data and analytics can be used to optimize reverse logistics processes by identifying trends in returns and making adjustments to the supply chain accordingly.