During the COVID pandemic, ineffective and overly complicated supply chains threw the healthcare industry into disarray. In 2019 alone, the valuation of the pharmaceutical industry was already worth 629 billion United States dollars, the existing problems make it even more complicated. The pandemic has made us realize that traditional approaches to managing an organization, individuals and resources can undermine the resilience of existing supply chains and their effectiveness in trying to recover from crises.

According to a report from Deloitte Health Solutions, strong commitment and spending are the main reasons for a company to achieve supply chain resilience. Now, many companies and organizations are taking advantage of technological developments to deal with existing disruptions (pandemic, cyber attacks, international trade crises). Even though technology plays an important role, it’s not the only way to do it.

What is resilience in supply chain management?

Resilience in supply chain management is a condition in which a company can sense and respond to a problem or risk in the supply chain as well as the ability to survive disruptions and recover from existing disruptions.

All industries have supply chain problems, and some businesses can’t avoid those problems. Back to the health industry that was discussed earlier, now the industry has made some friendly rules. Rules such as sterilization, assurance of traceability, and assurance of equivalent quality. To increase resilience and consistency in the supply chain, many medical and pharmaceutical industries are starting to adopt technology and automation.

The characteristics of a resilient supply chain

Production optimization with supply chain planning

With good supply chain planning and in line with production optimization, demand and supply can be optimally met and production becomes more aligned. Strategic planning is important to achieve resilience in all components of the supply chain which will provide transparency and flexibility. These actions can help companies reduce the impact of disruption and improve operations.

Utilization of data in work

Threats such as natural disasters, political issues, competitors’ activities, and sales reports can be analyzed using artificial intelligence and automation to be able to predict threats and opportunities that exist to achieve supply chain resilience. The use of technology and automation by businesses in determining inputs and outputs is one of the keys to achieving supply chain resilience.

Businesses are starting to use digital supply chain technologies such as artificial intelligence, machine learning, modern databases, and work device automation to see disruptions, trends, and opportunities.

Expand supply and manufacturing partners

Due to the COVID pandemic conditions, many businesses have finally realized the need for multiple suppliers to maintain a consistent and resilient supply chain. Usually, a business has only one supplier and manufacturer to prevent logistical complications, but when an urgent problem occurs it will impact the entire supply of goods. Having more than one supplier provides flexibility and certainty in the supply of goods.

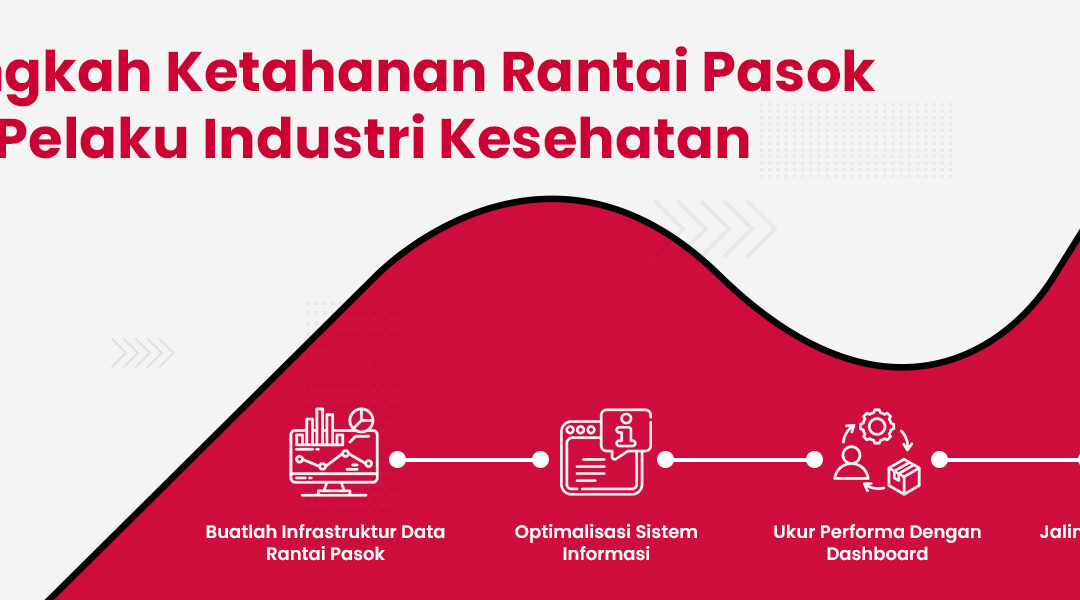

What are the 4 steps to developing a resilient supply chain?

In order to achieve supply chain resilience, policy makers in the health sector must do the following:

Create a supply chain data infrastructure

Improving the quality of data management will integrate data between the supply chain and existing systems at the clinic. You will get more accurate quality data from multiple sources to be able to solve existing inventory problems and provide a robust supply chain. Managing data is not an easy thing in business, therefore data must be put to good use to manage business.

Optimization of information systems

Recognize the strengths and weaknesses of the existing system, then optimize it to reduce unnecessary steps in the supply chain. Use an efficient inventory management system and company resource planning as a form of implementing supply chain resilience. Analyze data and other information to get accurate projections of inventory, workforce, technology and logistics needs.

Develop a supply chain performance measurement dashboard

Monitoring metrics and KPIs is critical to achieving supply chain resilience. Develop a supply chain performance measurement dashboard to continuously monitor the performance of suppliers, inventory management, purchases and acquisitions.

Establish cooperation with suppliers

Having a good relationship with suppliers is very important to maintain the supply of products and raw materials for supply chain resilience.

Conclusion

There are unmanageable disruptions or disturbances such as natural disasters, regional issues, geopolitical issues, and pandemics. As an online business entrepreneur or business entrepreneur engaged in the health sector, you cannot control this, but you can take preventive steps by building a strong supply chain.

The supply chain consists of a series of important processes and factors, if there is a slight inefficiency it will have an impact on the entire existing process. The use of technology and automation is a necessity for every business for efficiency.

NimbusPost is a logistics aggregator that offers delivery partner automation for you. You can freely choose more than 20 logistics partners according to your shipping needs.