Much like a flick of the wrist, a small ripple in consumer demand at your eCommerce store unexpectedly transforms into a wave when it reaches your suppliers. This is the Bullwhip Effect, an enigmatic yet crucial phenomenon in supply chain management that can make or break the success of your eCommerce business. It’s a concept that might sound as intricate as quantum physics but hits much closer to home for any business grappling with the unpredictability of market demands.

This blog post offers you a clear understanding of the Bullwhip Effect and, more importantly, practical strategies to mitigate its impact.

Understanding the Bullwhip Effect

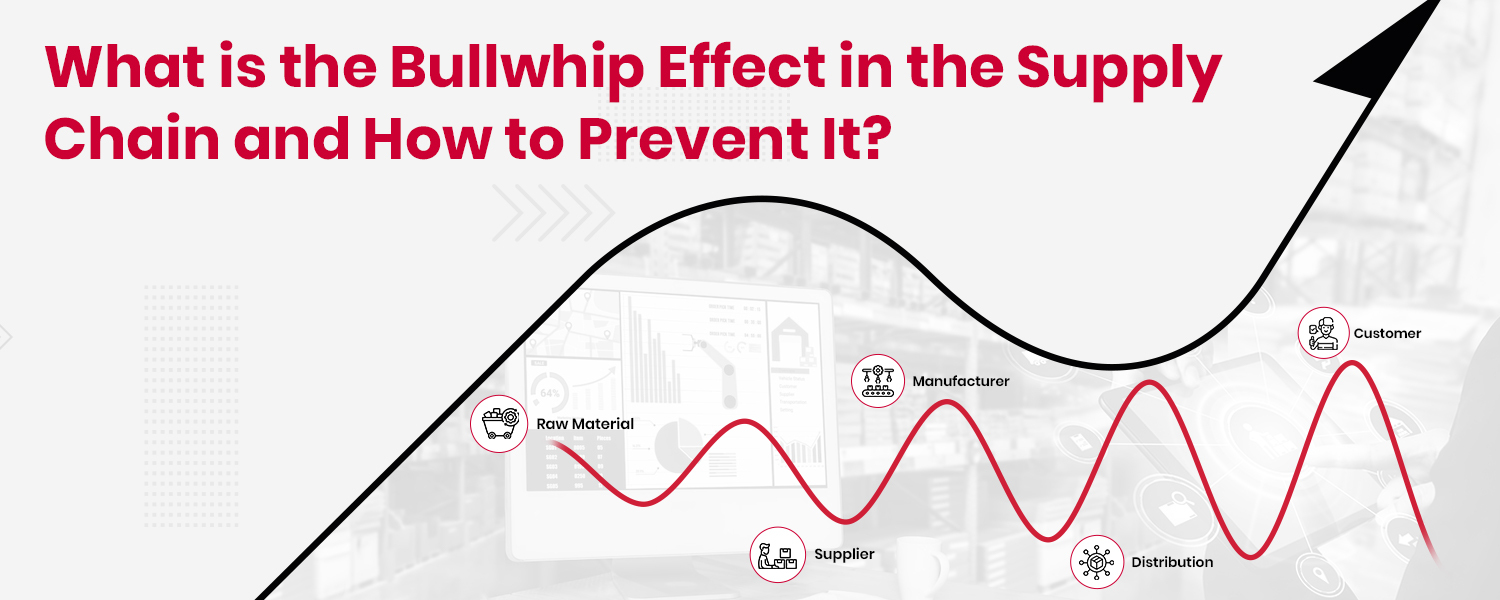

The Bullwhip Effect is a compelling and somewhat perplexing phenomenon. It’s where small shifts in consumer demand can cause disproportionately large waves of impact as you trace the path back up through the supply chain.

Imagine an eCommerce retailer noticing a slight uptick in selling a particular product. This minor change, often based on consumer behavior or market trends, might initially seem insignificant. However, as this information travels upstream—from retailers to distributors, then to manufacturers, and finally to raw material suppliers—each layer of the supply chain reacts, often excessively, to this perceived change in demand.

This reaction typically manifests in increased orders by each supply chain participant, magnifying the original change in demand. Consequently, what started as a minor fluctuation at the retail end can balloon into massive order spikes at the manufacturing level. This leads to inefficiencies such as overproduction and excess inventory and can cause significant financial strain and operational disruptions.

Causes of the Bullwhip Effect in eCommerce

Small Demand Fluctuations at the Retail Level

Even the smallest shift in consumer preferences or purchasing patterns in eCommerce can set off a chain reaction. This phenomenon stems from the reactive nature of supply chains. For instance, a slight increase in online orders for a specific product can lead retailers to order more from suppliers. Though minor at the retail level, this change starts a ripple effect that magnifies as it moves up the supply chain.

Rationing and Price Fluctuations

Rationing strategies, often employed to manage scarce resources, can significantly impact supply chain dynamics. When retailers limit the quantity of products available to consumers, it can create a false impression of heightened demand, leading suppliers to ramp up production unnecessarily. Also, price fluctuations play a critical role in shaping ordering patterns and inventory management. Periods of lower prices might lead to an artificial spike in demand, prompting retailers to order more. Conversely, price increases can lead to a sudden drop in orders, leaving suppliers with excess inventory.

Promotional Activities

Sales promotions are a double-edged sword in the context of the Bullwhip Effect. While they can boost sales in the short term, they often distort demand forecasting. For instance, a promotional discount might lead to a temporary surge in orders, which retailers might misinterpret as a lasting trend, leading to inflated orders to suppliers. Businesses must balance stimulating sales and maintaining a steady, predictable supply chain. Over-reliance on promotions can lead to erratic demand patterns, making it difficult for suppliers and manufacturers to plan production and inventory effectively.

Order Batching Practices

Order batching, a common practice in eCommerce, involves accumulating orders over a period and placing a bulk order. While this approach can be cost-effective, it often leads to sudden spikes in demand, thereby influencing inventory levels significantly. When orders are batched, suppliers may experience periods of inactivity followed by a rush of large orders, complicating inventory management and planning.

Forecasting Inaccuracies

Forecasting errors, however, can have far-reaching consequences. Overestimation of demand can lead to surplus inventory, increased holding costs, and potential wastage. Underestimation, on the other hand, can result in stockouts, lost sales, and customer dissatisfaction. These errors highlight the critical need for precise, data-driven forecasting methodologies in eCommerce to mitigate the Bullwhip Effect.

Impact of the Bullwhip Effect on eCommerce Businesses

Inventory Management Challenges

One of the most immediate impacts of the Bullwhip Effect in eCommerce is the challenge of managing inventory levels. Overstocking and understocking are common issues that arise when businesses misinterpret market demand signals. When inventory levels constantly fluctuate, allocating the right resources and space within a warehouse becomes challenging.

To mitigate these challenges, eCommerce businesses must adopt effective strategies that balance inventory levels. These include using sophisticated demand forecasting tools to consider various market variables and implementing just-in-time inventory management practices to reduce stock holding.

Increased Costs and Production Issues

The Bullwhip Effect can lead to significant increases in operational and holding costs. When demand forecasts are inaccurate, businesses often end up with excess inventory, increasing holding costs, or rush orders that drive up operational costs. Suppliers may struggle to cope with sudden large orders or frequent volume changes. This volatility can lead to strained relationships and may necessitate a reevaluation of procurement strategies.

Effects on Customer Service and Revenue

Customers expect fast and reliable last-mile delivery of their orders. Stockouts due to the Bullwhip Effect can lead to delays and unfulfilled orders, damaging the business’s reputation and customer trust. Transparency is key to maintaining customer trust amid supply chain fluctuations. Businesses should communicate openly with customers about product availability and potential delays. Offering alternative products or compensation can also help maintain a positive customer relationship.

Inefficiencies in Transportation and Production Scheduling

Unpredictable order volumes due to the Bullwhip Effect create significant challenges in transportation logistics. Businesses may face difficulties in optimising shipment loads, leading to increased transportation costs and inefficiencies. To optimise transportation and production, businesses can implement lean manufacturing principles, utilise advanced planning and scheduling systems, and adopt flexible transportation solutions that can adjust quickly to changing needs.

Strategies to Mitigate the Bullwhip Effect

Effective Communication Across Supply Chain Tiers

Effective communication across supply chain tiers is crucial in mitigating the Bullwhip Effect. Transparent communication ensures that accurate and timely information flows from one end of the supply chain to the other, helping to align perceptions of demand with reality. Techniques to enhance this flow include regular meetings, shared dashboards, and collaborative planning platforms.

Accurate Demand Forecasting and Data Analysis

The role of demand forecasting in reducing the Bullwhip Effect cannot be overstated. By utilizing advanced data analysis techniques, businesses can predict future demand more accurately, minimizing the risk of overordering or underordering. This involves looking at historical sales data and incorporating market trends, consumer behavior, and external factors like economic indicators.

Streamlining Supply Chain Operations

Streamlining supply chain operations involves simplifying processes, eliminating unnecessary steps, and optimizing the flow from suppliers to end consumers. Regularly reviewing and optimizing supply chain processes ensures that the supply chain is responsive and agile, capable of adapting to changes in demand without excessive inventory buildup.

Technology Integration in Supply Chain Management

Modern supply chain management systems provide real-time visibility, analytics, and predictive modeling, which are essential for responding quickly and accurately to market changes. The use of technology in supply chain management leads to better coordination, forecasting, and responsiveness.

Role of ERP and Inventory Management Software

ERP (Enterprise Resource Planning) systems are significant in centralizing data management and providing a unified view of the supply chain. These systems help manage orders, track inventory, and analyze sales data. Warehouse inventory management software specifically contributes to maintaining accurate stock levels and preventing excess inventory and stockouts.

Supplier Portals and EDI Transactions

Supplier portals and Electronic Data Interchange (EDI) transactions effectively stream supplier communication and enhance data exchange accuracy. Supplier portals provide a platform for easy information sharing and collaboration. At the same time, EDI facilitates the electronic exchange of standard business documents, such as purchase orders and invoices, reducing errors and improving processing speed.

Turning Challenges into Opportunities

Learning from the Bullwhip Effect to Improve Inventory Management

The Bullwhip Effect, often seen as a challenge in supply chain management, can be a valuable learning tool for improving inventory management. By analyzing the root causes and the ripple effects of this phenomenon, businesses can gain critical insights into their inventory dynamics. This analysis helps identify areas where demand forecasting can be enhanced, leading to more accurate inventory levels.

Gaining Market Leverage and Enhancing Efficiency

By recognising the patterns and triggers of this effect, companies can better anticipate market trends and adapt their strategies accordingly. This foresight can be a powerful tool in gaining a competitive advantage, allowing businesses to respond proactively rather than reactively to market changes. Enhanced efficiency is often the result of a deeper understanding of supply chain dynamics, leading to optimised processes and resource allocation.

Strategic Marketing Approaches for Demand Stimulation

By analyzing how demand fluctuations affect the supply chain, businesses can develop marketing strategies that are more aligned with supply chain capabilities and consumer demand patterns. Effective demand stimulation campaigns need to be carefully planned to avoid exacerbating the Bullwhip Effect, focusing instead on creating sustainable demand.

Adapting to Market Dynamics for Competitive Advantage

The Bullwhip Effect teaches businesses the importance of being flexible and responsive to market dynamics. Strategies to stay ahead in a rapidly changing market include:

- Investing in technology that provides real-time data.

- Fostering a culture of continuous improvement.

- Developing flexible supply chain processes.

Conclusion

As we reach the conclusion, it’s clear that eCommerce, with its rapid demand fluctuations and supply chain complexities, requires a vigilant and adaptive approach. By understanding and addressing the challenges the Bullwhip Effect poses, eCommerce businesses can turn potential vulnerabilities into strengths. With logistics management platforms like NimbusPost, businesses can turn the supply chain into a strategic asset.

NimbusPost allows eCommerce businesses to manage their supply chain from a single platform. You can manage your warehouses across countries, manage bulk shipments with multiple third-party logistics carriers, and can also find the best 3PL logistics companies in India.