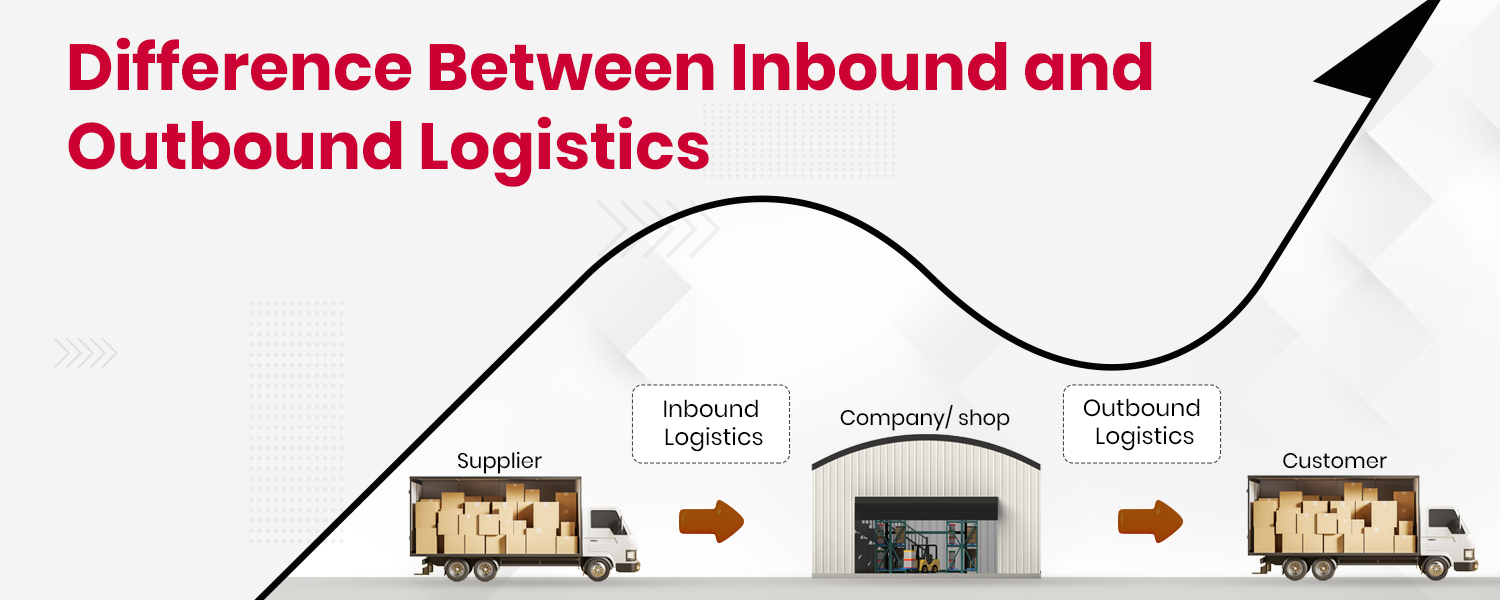

As an eCommerce business, the efficiency of your supply chain management hinges on understanding the two contrasting yet interconnected performers – Inbound and Outbound Logistics. Inbound logistics involves orchestrating goods from suppliers to your warehouse; parallel, outbound logistics is the visible face of your business, the part your customers interact with.

Yet, the question lingers: What precisely differentiates inbound from outbound logistics? Why is this distinction a cornerstone for any thriving eCommerce business?

As you read this blog, delving into this query, prepare yourself to understand the nuances that make inbound and outbound logistics distinct yet symbiotic forces – forces that can make or break the success of your eCommerce logistics operations.

What is Inbound Logistics?

Inbound logistics is a multifaceted process of sourcing, receiving, storing, and handling goods. It begins far from the spotlight of consumer interactions but sets the stage for every success that follows. Suppose you peel back the layers of this complex process. In that case, it’s about bringing in the raw materials, components, or products necessary for a business to thrive effectively, efficiently, and at the right time.

Without a steady, reliable, and efficient supply of the right goods at the right time and in the right condition, the entire eCommerce ecosystem could falter. Inbound logistics ensures businesses have the necessary inventory to meet customer demands, respond to market trends, and maintain a competitive edge.

What is Outbound Logistics?

Outbound logistics is the strategic transportation of goods from a business to the end user. This might seem straightforward, but the devil, as they say, is in the details. Outbound logistics is the culmination of meticulous planning and execution that ensures a flawless product journey from warehouse shelf to customer doorstep.

In today’s digital age, where customer satisfaction is paramount, mastering outbound logistics is indispensable. It’s a complex puzzle that, when solved correctly, can lead to a seamless customer experience, timely deliveries, and, ultimately, the success of an eCommerce business.

What is the Difference Between Inbound and Outbound Logistics?

While appearing similar, the terms ‘Inbound’ and ‘Outbound’ Logistics play distinctly different yet equally pivotal roles in the supply chain. Let’s understand these differences.

Focal Points

Inbound logistics is all about the inward movement of goods. It’s the strategic process of sourcing and receiving materials – raw materials for production or products for sale. Imagine it as laying the groundwork, the preparation phase where a business stocks up on its essentials.

In stark contrast, outbound logistics is the outward movement of these prepared goods towards their final destination – the customers. This is where the products, once a part of inventory, begin their journey to fulfill customer demands.

Critical Role

The role of inbound logistics can’t be understated, as it forms the backbone of production and sales. It’s about getting the right materials in the right quantity, at the right time, and at the right price. This is the phase where businesses prepare for what lies ahead – meeting market demands.

Conversely, outbound logistics plays a critical role in customer satisfaction. It’s the last mile in the logistics chain – encompassing everything from when a product leaves the warehouse until it reaches the consumer. Its efficiency is directly proportional to customer delight and retention.

Process Involved

Delving deeper into processes, inbound logistics involves a series of steps – sourcing the right suppliers, placing orders, managing transportation, receiving shipments, conducting quality checks, and efficient warehouse inventory management. Each step is crucial, as a misstep could ripple through the entire supply chain.

Outbound logistics, though seemingly straightforward, involves its complexities – processing orders, picking and packing goods precisely, managing carriers and shipments, and ensuring products reach their destination as promised. It’s a blend of speed, accuracy, and customer focus.

Key Relationships

Inbound logistics relationships are predominantly with suppliers, manufacturers, and distributors. It’s more of negotiations, reliability, and quality assurance.

Outbound logistics, however, centers its relationships around distribution channels, retail partners, and, most importantly, the end consumers. Here, the focus is on fulfillment and satisfaction, building a bridge between the business and its market.

Activities Involved

Inbound logistics is characterised by procurement, conducting stringent quality controls, ensuring efficient storage in inventories, and managing reverse logistics when needed.

Outbound logistics, in contrast, is an arena of order fulfillment, meticulous packaging, warehousing, managing transportation logistics, and providing top-notch customer service.

How Inbound and Outbound Logistics Works as a part in eCommerce

Steps in Inbound Logistics (Receiving)

Purchasing and Sourcing: This crucial step involves identifying and procuring products or raw materials essential for the business’s operations. Strategic sourcing is not merely about finding suppliers but establishing partnerships that ensure cost-effectiveness and quality assurance.

Recording and Receipts: This phase is crucial for maintaining a transparent and traceable record of what has been ordered, the quantity, the expected delivery dates, and the purchase terms. Accurate record-keeping plays a fundamental role in inventory management. It ensures that the business clearly understands incoming stock, which aids in planning for storage space and further logistics processes.

Load Arrival: This phase requires coordination between the warehouse staff, logistics teams, and, sometimes, the suppliers. It involves preparing for the incoming shipment, allocating docking spaces, and ensuring the necessary equipment and personnel are available to handle the load.

Receiving: This step involves accepting, inspecting, and sorting the incoming goods. Quality checks are a significant part of this process, where items are inspected for damage or discrepancies.

Reverse Logistics: This process deals with the return of goods from customers or the handling of unsatisfactory supplier shipments. Efficient reverse logistics is crucial for maintaining customer satisfaction and ensuring inventory accuracy.

Steps in Outbound Logistics (Shipping)

Customer Order: The outbound logistics process commences when a customer orders. This stage is critical, setting the tone for the entire shipping and delivery process.

Order Processing: Once an order is received, the next step is processing, which involves confirming that the ordered items are in stock and reserving them for the specific order. Efficient order processing requires a robust order management system that can update in real time, ensuring that stock levels are accurate.

Picking: Picking is retrieving the ordered products from their inventory locations for shipping. Many eCommerce businesses invest in advanced picking solutions like automated picking systems or pick-to-light technology to enhance accuracy and speed.

Packing, Staging, and Loading: Once items are picked, they must be properly packaged for shipment, ensuring that products are securely packaged to prevent damage during transit. After packing, items are staged and loaded onto delivery trucks.

Shipping: The shipping phase chooses the appropriate shipping method based on delivery deadlines, costs, and customer preferences.

Last Mile Delivery: Last-mile delivery is the final step in outbound logistics, where products are delivered to the end customer.

What are the Crucial Inbound and Outbound KPIs?

Crucial Inbound Logistics KPIs

Supplier On-Time Delivery: This KPI measures how consistently suppliers deliver goods within the agreed-upon timeframe. The significance of this metric lies in its direct impact on inventory levels and production schedules.

Inventory Turnover Rate: Inventory Turnover Rate is a pivotal KPI that reflects how often inventory is sold and replaced over a specific period. A high turnover rate generally indicates effective inventory management, signifying that a company is selling goods quickly and not overstocking.

Freight Bill Accuracy: Freight Bill Accuracy as a KPI measures the precision of transportation invoicing. Discrepancies in freight bills, such as overcharges or misclassified items, can significantly affect a company’s budgeting and financial planning.

Receiving Efficiency: Receiving Efficiency measures how swiftly and accurately a company’s warehouse receives inbound shipments.

Quality of Received Goods: This KPI tracks the rate of defective or damaged goods received from suppliers.

Crucial Outbound Logistics KPIs

Order Accuracy Rate: This KPI measures the proportion of orders shipped without errors. The accuracy of fulfilling orders is fundamental because it directly impacts customer satisfaction and loyalty.

Order Processing Time: Order Processing Time is a vital KPI that tracks the efficiency from when an order is received to when it is dispatched. It impacts the overall speed of delivery, which is a significant factor.

Shipping Time and Costs: The efficiency of the shipping process and its associated costs are key concerns in outbound logistics, making shipping time and costs an essential KPI.

Delivery On-Time Rate: The Delivery On-Time Rate is a critical measure of punctual customer deliveries. A high on-time delivery rate indicates an efficient logistics process and can be a significant competitive advantage in retaining customers.

How to Master Inbound & Outbound Logistics?

Optimise Stock Levels

Maintaining an optimal inventory is crucial to avoid logistical issues like overstocking or stockouts, which can severely disrupt operations. Businesses need to leverage data analytics and market research to improve predictions on product demand and sales trends. This approach involves analysing historical sales data, understanding market trends, and forecasting future demand based on various factors, including seasonal fluctuations and consumer behaviour.

Increasing Automation

In the modern logistics industry, automation is pivotal in enhancing operational efficiency. Businesses can significantly reduce manual labour, aggregate valuable data insights, and improve speed and accuracy by automating key logistics processes such as order processing, shipping, and inventory management.

Tracking

Effective tracking of inbound and outbound freight is essential for improved accuracy and efficiency in logistics management. Therefore, by implementing robust tracking systems, businesses can monitor the movement of goods at every stage, from supplier to customer. This enhanced visibility helps identify bottlenecks, optimise transportation routes, and accurately manage inventory levels.

Route Optimisation

Route optimisation involves utilising software and technology to determine the most efficient routes for receiving raw materials and delivering finished goods. Route optimisation software can analyse various factors such as traffic patterns, distance, carrier availability, and delivery windows to propose the most efficient routes. This contributes to cost reduction and enhances customer satisfaction by ensuring timely deliveries.

Enterprise Resource Planning (ERP)

ERP systems offer a centralised platform to manage various business functions, including logistics, finance, HR, and sales. In logistics, ERP systems can manage everything from inventory levels to order processing and supplier relationships. Integrating ERP systems in logistics provides a holistic view of the supply chain, enhances data accuracy, and facilitates better decision making.

Conclusion

Mastering both inbound and outbound logistics can be a critical determinant of success. The interplay between these two logistics arms is like the two wheels of a cart – both need to function seamlessly for the cart to move forward. Fueling up your eCommerce cart, NimbusPost offers you a plethora of 3PL carriers to choose from the best of the best. Moreover, you can get a bird’s eye view of freight transportation and the overall supply chain from a single platform.

FAQ

What are the 5 Inbound and Outbound Logistics Challenges?

Supplier Reliability and Delays

Unreliable suppliers can cause significant disruptions in the supply chain, leading to production delays, inventory shortages, and compromised product quality.

Inventory Management Complexity

Striking the right balance in inventory management is a complex task. Additionally, managing storage space effectively to accommodate inventory is a challenge, especially for businesses with a wide range of products.

Rising Transportation Costs

The increasing costs associated with shipping and receiving goods are a significant concern in both inbound and outbound logistics.

Last-Mile Delivery Complexities

Last-mile delivery poses numerous challenges. These include managing delivery time expectations, navigating urban traffic, and routing complexities.

Reverse Logistics

This aspect is often complex and resource-intensive, involving processes like return merchandise authorisation, inspection of returned goods, processing refunds or exchanges, and restocking or disposing of returned items.

Why Are Inbound and Outbound Logistics Important?

- Inbound and outbound logistics are fundamental components of the supply chain.

- Inbound and outbound logistics significantly impact a business’s overall costs.

- Businesses that manage their inbound and outbound logistics gain a competitive edge in the market.

- Inbound logistics is important for quality control, as it involves inspecting and verifying the quality of materials and products received from suppliers.

- Efficient logistics contribute to revenue growth by enabling businesses to meet market demands promptly, reduce operational costs, and improve customer service.