In today’s globalised world, cold chain logistics is like a thread that connects producers and consumers, a bridge that ensures the integrity and safety of temperature-sensitive goods in supply chain management.

However, managing this intricate storage, transportation, and delivery network is no walk in the park. It requires careful planning, execution, and a keen understanding of the technologies and trends shaping the future of cold chain logistics.

Therefore, whether you’re a business owner, or an eCommerce start-up, the following exploration of cold chain logistics and its management will offer valuable insights. In this blog, we aim to simplify cold chain logistics and shed light on the significance of its management in driving efficiency, reducing waste, and enhancing customer satisfaction.

What is Cold Chain Logistics?

Cold chain logistics, a term that rolls off the tongue, is a critical cog in global commerce. The science-backed, technology-infused process ensures the safe transportation of temperature-sensitive goods along the supply chain.

It is an interconnected network involving the storage and transportation of temperature-sensitive products at optimal conditions throughout their transit. This includes elements like:

Cold Storage: They are meticulously designed and monitored to maintain the required temperature levels.

Cooling Systems: These are the powerhouse that maintains the appropriate temperature throughout the journey of the goods—from processing to storage and transport—thereby keeping the products in their prime.

Cold Transport: This includes the carrier that ensures goods retain their freshness by maintaining stable temperature and humidity levels during transit.

Cold Processing: These facilities process goods, keeping sanitation paramount and ensuring their safety and quality.

Cold Distribution: This involves the streamlined process of loading boxes, crates, or pallets to distribute goods while ensuring temperature control.

Each of these components, working in a seamless interplay, upholds the vitality of cold chain logistics, ensuring our access to safe, quality products, irrespective of geographical boundaries.

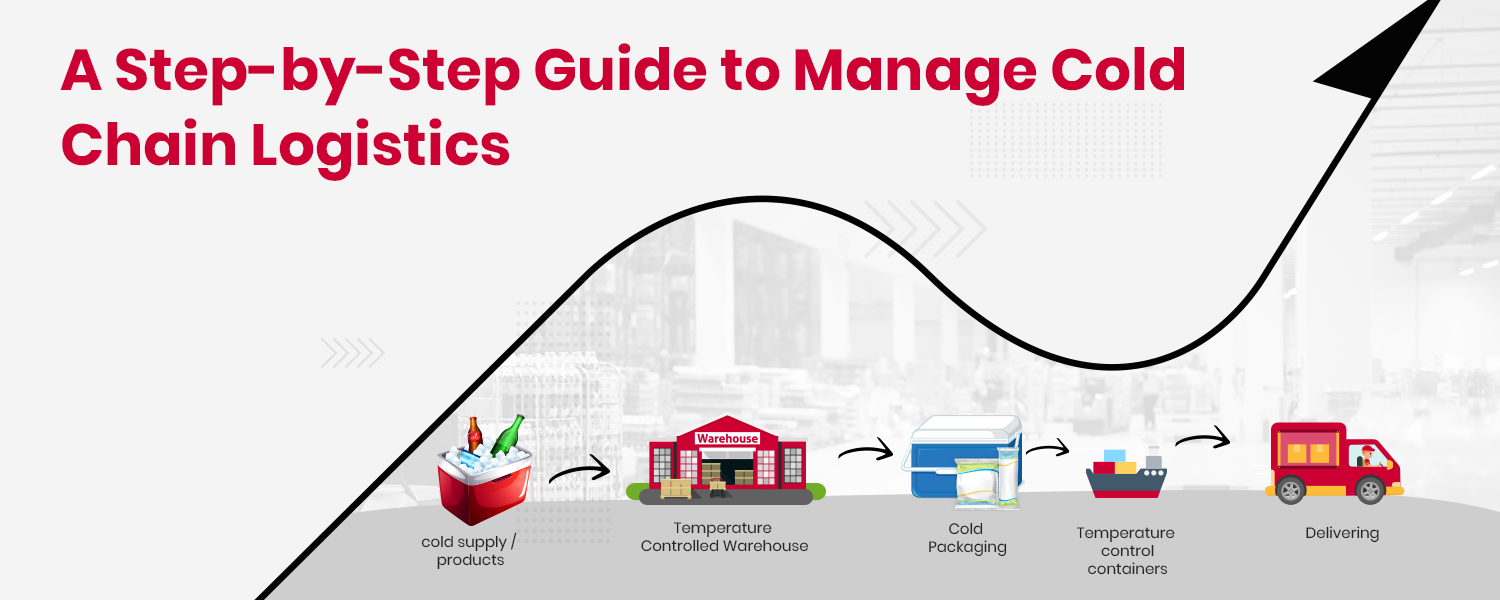

How to Manage Cold Chain Logistics: A Step-by-Step Guide

Storage

In order to preserve the quality and lifespan of products, it is essential to know the ideal storage temperature for each type. This involves knowing the perishability of each item and the best temperature conditions for it.

Once determined, selecting a cold storage facility equipped to maintain these temperatures is paramount. The facility must also accommodate efficient inventory management techniques, like the First-In, First-Out (FIFO) strategy, to prevent product expiration and ensure continual stock rotation.

Packaging

Packaging in cold chain logistics extends beyond mere containment; it’s integral to the maintenance of product quality and safety. Hence, understanding the specific packaging requirements for each product type is crucial.

Invest in innovative packaging solutions designed to keep products at their optimal temperature while ensuring safety during transit. It’s equally essential to be aware of and comply with the regulatory guidelines related to cold chain packaging, as these may vary across different regions and products.

Tracking

Technological advancements like the Internet of Things (IoT) offer real-time monitoring capabilities for cold chain logistics, creating an always-on, real-time overview of your products. In addition, data analysis techniques can ensure the optimum functionality of your cold chain infrastructure and predict necessary maintenance, preventing costly downtime. Additionally, Artificial Intelligence (AI) and Machine Learning (ML) can provide predictive analytics, reducing errors and enhancing decision-making capabilities, which ultimately streamlines the entire tracking process.

Transportation

Transportation in cold chain logistics requires choosing the right mode based on product type, distance, cost, and transit time. Vehicles equipped with advanced temperature-control capabilities are a must to ensure products remain at their optimal temperature throughout the journey. It’s also crucial to monitor the transportation process closely, looking out for any temperature deviations or unexpected delays that could compromise product quality.

Customs Clearance

In international cold chain logistics, understanding the customs regulations of different countries or regions is key to ensuring smooth operations. Preparing the necessary documentation in advance can expedite the customs clearance process, avoiding delays that might jeopardize product quality. Therefore, swift and effective clearance procedures are vital to maintaining the integrity of the cold chain.

Product Management

From procurement to delivery, managing the product lifecycle is essential in cold chain logistics. This involves ensuring product quality and safety at all times, tracking product expiration dates, and maintaining appropriate storage and transport conditions. In case of a quality issue, having efficient recall procedures in place can prevent further distribution of the affected product, protecting both consumer safety and your brand’s reputation.

Delivery

Coordinating timely delivery schedules is the final step in successful cold-chain logistics. Ensure the final delivery point, whether a store or a consumer’s home, maintains the required product temperature until it’s used or sold. Manage any delivery exceptions proactively and have strategies to resolve them effectively. After all, the success of cold chain logistics hinges on the successful delivery of products in their optimal condition.

What is the Importance of Managing Cold Chain Logistics?

Quality and Integrity of Products

Inadequate temperature control can affect product texture, flavour, and shelf life, undermining consumer trust and damaging brand reputation. Thus, it is vital to manage cold chain logistics meticulously to uphold the quality of goods and products, ensuring they reach consumers in their best state.

Ensuring the Safety of Products

Cold chain logistics play a vital role in ensuring product safety, particularly for temperature-sensitive products like food and pharmaceuticals. Improper handling or temperature variations can make these products unsafe for consumption or use, posing public health risks. Therefore, effective management of cold chain logistics is key to safeguarding public health by ensuring the safe transportation and storage of these products.

Reducing Wastage and Minimising Losses

Cold chain logistics management can significantly reduce this wastage by ensuring strict temperature control and efficient transportation, leading to substantial economic savings.

Boosting Operational Efficiency

When enhanced by the latest technologies like AI, IoT, and automation, cold chain logistics management can streamline operations and increase efficiency.

What are Technologies Driving Cold Chain Logistics?

Warehouse and Distribution Center Automation

Smart warehousing and automation have significantly transformed cold storage warehouses and distribution centres. These centres now operate at unprecedented efficiency levels by integrating technologies like autonomous vehicles, automated storage and retrieval systems, and advanced conveyor systems. The upshot of this is enhanced productivity and a more agile response to fluctuating demand patterns.

Robotics Technology

Robotics has marked its territory in the cold chain logistics industry, from automated picking and sorting to intelligent packaging processes. Predictions indicate that the robotics market within this industry will continue to grow, given its remarkable benefits.

Internet of Things (IoT)

The Internet of Things (IoT) brings an extra layer of visibility and control to the cold chain. From sensors that continuously monitor the temperature to systems that track real-time location, IoT offers numerous benefits.

Artificial Intelligence and Machine Learning

Artificial Intelligence (AI) and Machine Learning (ML) are revolutionizing cold chain logistics by improving transparency and predictive capabilities. These technologies process real-time data and offer improved decision-making strategies, leading to optimized operations. From predictive analytics that forewarn potential disruptions to error reduction mechanisms, AI and ML unlock a new level of sophistication in managing cold chains.

What are the Top Trends in Cold Chain Management?

Less Than Truckload (LTL) Transportation

As industries move towards cost-efficient and flexible shipping options, Less Than Truckload (LTL) transportation has emerged as a pivotal trend in cold chain management. LTL offers the benefit of transporting smaller quantities of goods without requiring a full truckload, making it both cost-effective and efficient.

GPS Technology

In today’s digital age, the importance of real-time tracking cannot be overstated. GPS technology supports cold chain management by ensuring precise tracking and maintaining the safety of temperature-sensitive products. We can expect more sophisticated GPS tracking systems with predictive capabilities and integration with other technologies like IoT and AI as technology advances.

Last Mile Delivery

In the context of cold chain logistics, last-mile delivery stands as the final and arguably the most critical step in this supply chain model. Innovations in this area, such as drone deliveries and autonomous vehicles, have started to reshape the landscape of last-mile delivery, ensuring the product reaches the consumer in optimal condition.

Green and Sustainable Practices

With growing global concern for environmental sustainability, the cold chain industry is not exempt from the pressure to go green. Sustainable practices in cold chain management include optimising energy use, reducing greenhouse gas emissions, and using eco-friendly refrigerants. These efforts can lead to long-term cost savings, improved customer reputation, and compliance with increasing regulatory requirements.

Digital Twin Technology

Digital Twin technology, a virtual model of a process, product, or service, is another game-changing trend in cold chain management. This technology aids in the visualisation, analysis, and optimisation of cold chain logistics by replicating the real-world scenario in a digital platform. It can improve efficiency, minimise errors, and offer insights for strategic decision-making.

Conclusion

In an interconnected world where goods crisscross the globe, cold chain logistics stands as a streamlined process. It ensures our fruits are ripe and ready, and our vaccines are available, enabling healthcare supply chain resiliency, as well as ensuring our businesses run with clockwork precision, satisfying customers and forging ahead in competitive markets.

For businesses, mastering cold chain logistics management will be more than just a necessity—it will be a key driver for success, a differentiator that will separate leaders from followers in the market.

FAQs

What is an example of cold chain logistics?

The most relevant example of cold chain logistics is Vaccines, certain medications, and biological samples, which require a strictly controlled cold environment to maintain their efficacy.

What are the 2 types of cold chains?

The two types of chain chains are:

- Active cold chain

- Passive cold chain

What are the advantages of cold chain logistics?

Cold Chain Logistics offers numerous advantages, including:

- Cold chain logistics maintains the quality of temperature-sensitive products during storage and transport, ensuring they reach the consumer in optimal condition.

- By maintaining proper temperature control, it reduces the risk of foodborne illnesses.

- Cold chain logistics facilitates the global export and import of perishable goods, opening up new markets for businesses.

What is the risk of cold chain logistics?

Cold chain logistics comes with several potential risks:

- Deviations or fluctuations from required temperatures can lead to spoilage or loss of product efficacy.

- Cold storage and transport equipment may fail, compromising the cold chain.

- Packaging that doesn’t provide enough insulation can lead to temperature fluctuations.

Who needs cold chain logistics?

Several sectors, like Pharmaceuticals, food and beverages, agriculture, and the chemical industry, require cold chain logistics for the safe and efficient transport of their goods.